General Wood Species Attributes

Some things to consider when selecting paddle materials are weight, density, hardness and working characteristics and appearance. Below are some charts representing some of these qualities as they relate to different species as well as written descriptions of species attributes.

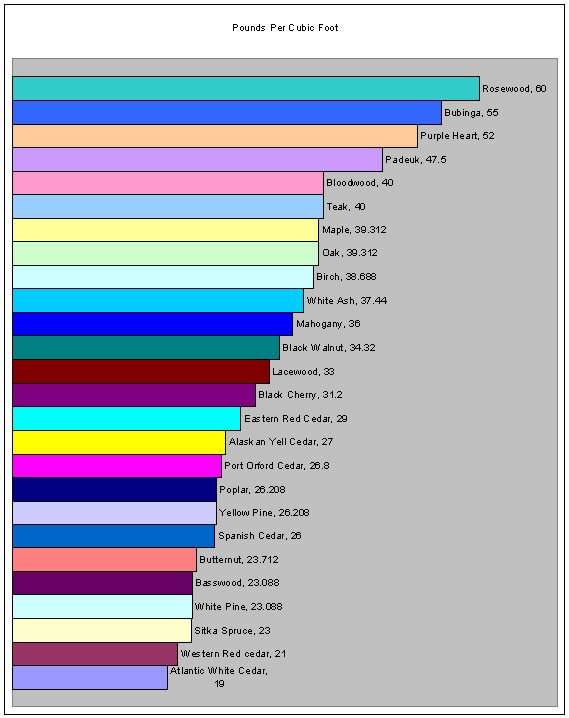

Weight

The weight of lumber is measured in Pounds per cubic foot (lbs/cu. ft.). The graph below lists some common wood species and their weight. Generally heavier wood is more resistant to wear but.... it's heavier. Remember increased weight means increased density, in other words less buoyant.

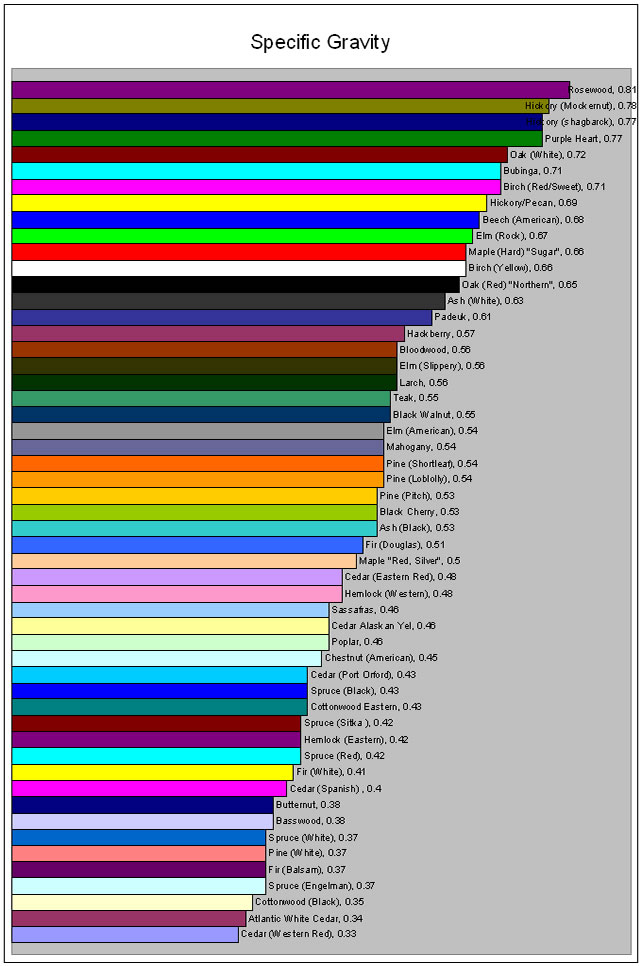

When measuring the density of wood a ratio called specific gravity is used.

Specific Gravity

Specific Gravity is a comparative measurement of a materials density to that of water. Water is used as a base line for specific gravity and is given a value of 1. All other materials are compared to water and expressed as a ratio heavier or lighter in density. As specific gravity is a comparison tool, it can be applied across any units of any material. Lumber with a specific gravity greater than 1.0 will sink in water. Lumber with a specific gravity less than 1.0 will float. As specific gravity drops farther below 1.0 buoyancy increases

The density of pure water is 62.4 lbs/cu.ft (pounds per cubic foot) and if a sample of apple has a specific gravity of 0.73 then we can calculate that its density is 0.73 x 62.4 = 45.552 lbs/cu.ft.

Note, kg/cu.m divided by 16.01846 = lbs/cu.ft.

While this measure is similar to lbs/cu.ft. It is good to know the meaning of this measurement as it is commonly used in the timber/lumber to describe wood characteristics.

For more information see the Wood Products Handbook

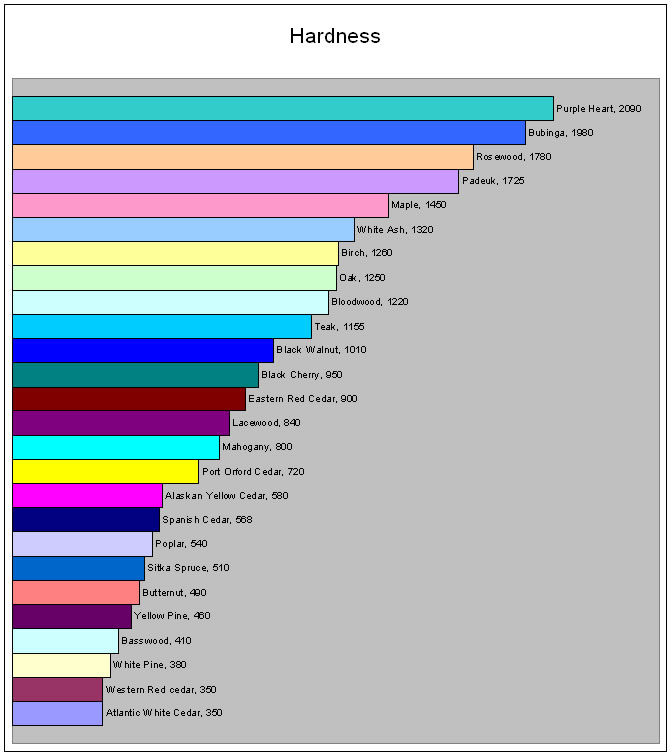

Relative Hardness

The harder the wood, the better it resists wear, the less it crushes or mashes under load and the better it can be polished. This is an interesting and important measurement . Notice that relative hardness does not directly correlate to its pounds per cubic ft. or its specific gravity as it is compared to other species.

Tree Growth

When trees grow they expand their trunks by addition new peripheral rings layers. if you look at the end of a cut log you can see a series of concentric rings. These growth rings each represent one year of growth. each ring may have two parts, a lighter part (early wood) that represents the fast growth that happens during the early season, and the darker part that represents the slower growth (late wood) that occurs during the late season. environmental and climatic conditions will effect the amount of growth each season and thus the size of each part of a each ring. large ring show a favorable growing years small ring show less favorable growth conditions. tropical and sub tropical trees which are exposed to favorable growth conditions year round may not show growth rings at all.

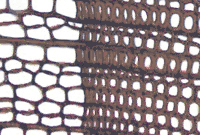

The image on the right shows a section view of a growth ring and 100x. The early wood is the area with thin walls and large cell cavities. The late wood is the area with the thicker cell walls and smaller cell cavity. Since the late wood is slow growing with thick cell walls it is more dense then early wood. In general slower growing trees will have stronger or more dense wood then fast growing trees.

The image on the right shows a section view of a growth ring and 100x. The early wood is the area with thin walls and large cell cavities. The late wood is the area with the thicker cell walls and smaller cell cavity. Since the late wood is slow growing with thick cell walls it is more dense then early wood. In general slower growing trees will have stronger or more dense wood then fast growing trees.

Milled Lumber

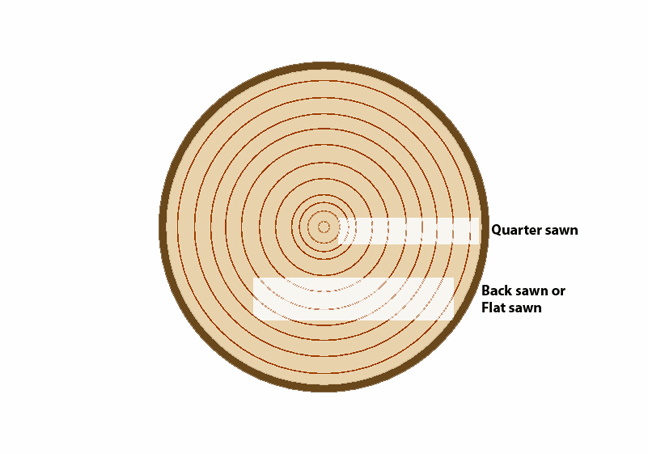

When a log is cut into boards a variety of sawing pattern are used. Different saw patterns produces boards with different grain patterns relative to the boards surface. The grain pattern in lumber refers to the way that the growth rings are represented relative to the boards face or surface. If a board is cut so that the growth rings are tangential with the boards face it is called flat sawn. (the annual rings form angles of 0 to 45 degrees with the surface of the piece.) This produces less expensive lumber. When a board is cut so that the growth rings are radial to the surface (the annual rings form angles of 45 to 90 degrees with the surface of the piece.) it is called quarter sawn and produces a higher quality lumber.

Lumber Movement

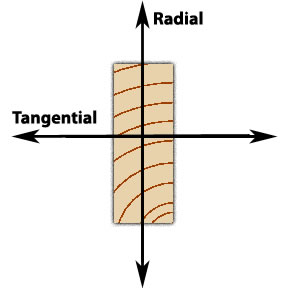

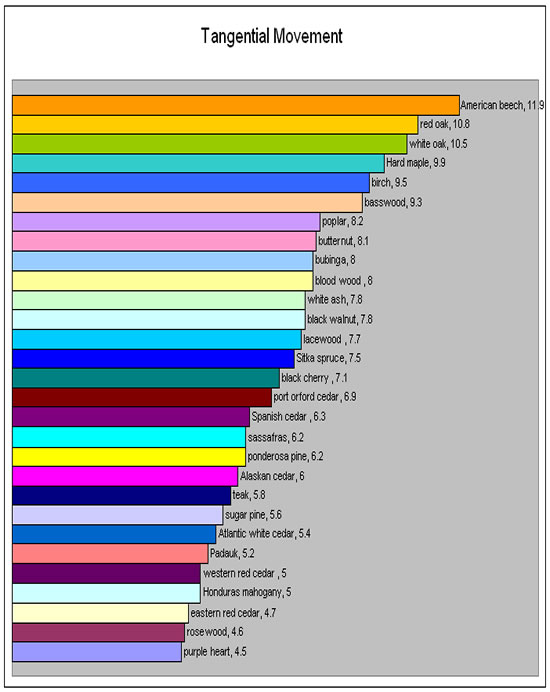

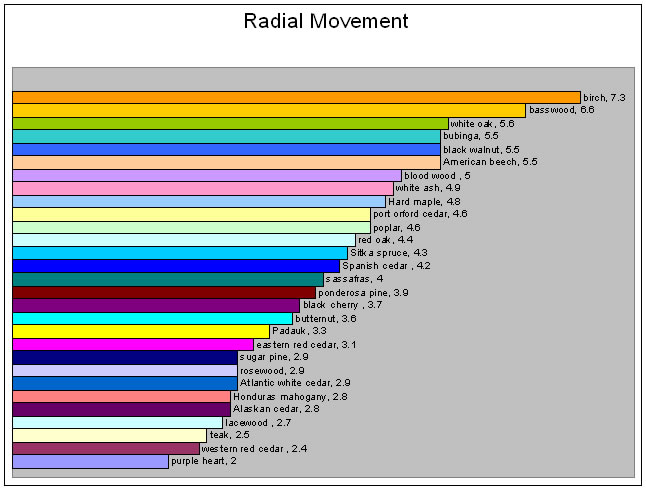

Wood shrinks and expands as its moisture content changes. This happens in your house, when it rains some wooden doors may stick a bit. That is because the wood has expanded. When using wood near water like in boats and paddles this can be an important consideration. it is also a concern when laminating two different types of wood because different wood species have different expansion rates. If that's not enough to think about expansion rates are different within species based on the direction of the expansion relative the grain orientation. The two directions of expansion are called radial and tangential movement. These two directions of movement are illustrated in the image at the right.

Wood shrinks and expands as its moisture content changes. This happens in your house, when it rains some wooden doors may stick a bit. That is because the wood has expanded. When using wood near water like in boats and paddles this can be an important consideration. it is also a concern when laminating two different types of wood because different wood species have different expansion rates. If that's not enough to think about expansion rates are different within species based on the direction of the expansion relative the grain orientation. The two directions of expansion are called radial and tangential movement. These two directions of movement are illustrated in the image at the right.

Below are some charts showing the movement rates for some common wood species. for more information about movement do a web search and you can find information on this topic.

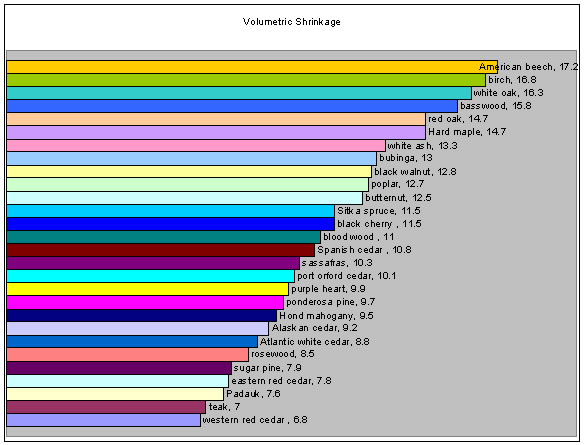

Shrinkage

Volumetric shrinkage is a term used to answer the question "how stable is this wood". Values shown describe the shrinkage of the wood from green to oven dry. Since this is a measure of volume, both tangential and radial movement are considered in this number. This is a good number for comparing overall values between species.

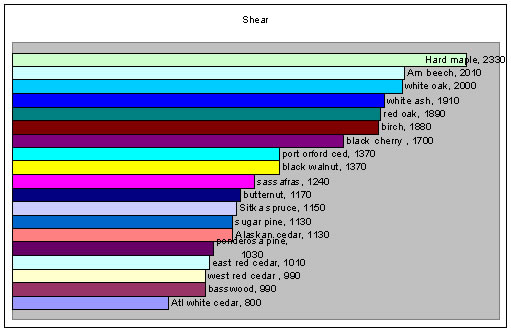

Shear Stress

The formunla for shear strees is force acting tangentailly to a surface divided by the surface area. This is usually use to determine beam strengt. For us it is an indication of general bend and breakabilty.

Source data for this page came from: United States Forestry Service ,Department of Agriculture handbook No. 450 and, the forest product research labs wood hand book.

rbanner

rbanner